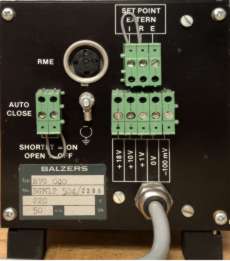

Automatic regulating valve RME010

Automatic regulating valve RME010Automatic Vacuum Gas Regulating Device

The Balzers RME010 regulating valve and the RVG040 valve control unit are the components of an automatic and instantaneous regulating device for maintaining constant pressure, partial pressure or gas flow when admitting gas to a vacuum plant.

Gas flow range is <10-4 to 50 torr litre/seconde.

Automatic regulating valve RME010

Automatic regulating valve RME010

Control circuit

Proportional gain Vp

5

150

Reset time Trn 0.1

2 s

Input signal +18v, +10V, 1V, -100mV

Set point 0

1000

Output RME connector to dosing

valve 0

16V

Display

Dosing valve voltage 0

16V

Fuse

Set Point Intern

or Extern

Auto close shorted / open

Power display LED

Power switch On / Off

Power 230V 50 60Hz

Setting the Control for gas pressure regulation

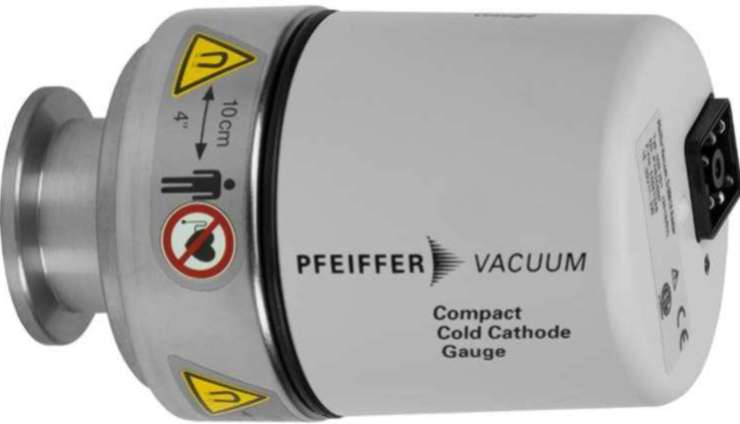

The Automatic Vacuum Gas Regulating Device is used with a Balzers SingleGauge PKR251 and associated RVG040 Control Unit to regulate the pressure in the vacuum plant.

The regulated pressure is set up by adjusting the SET POINT multi-tour knob on the RVG040 Valve Control Unit. The PKR215 vacuum single gauge has an analog output range of 0 +10 V, the corresponds to the SET POINT on the RVG040.

For example, if the SET POINT knob is adjusted to 380, the pressure will be controlled according to a proportional analog output voltage of 3.8 V on the total pressure gauge.

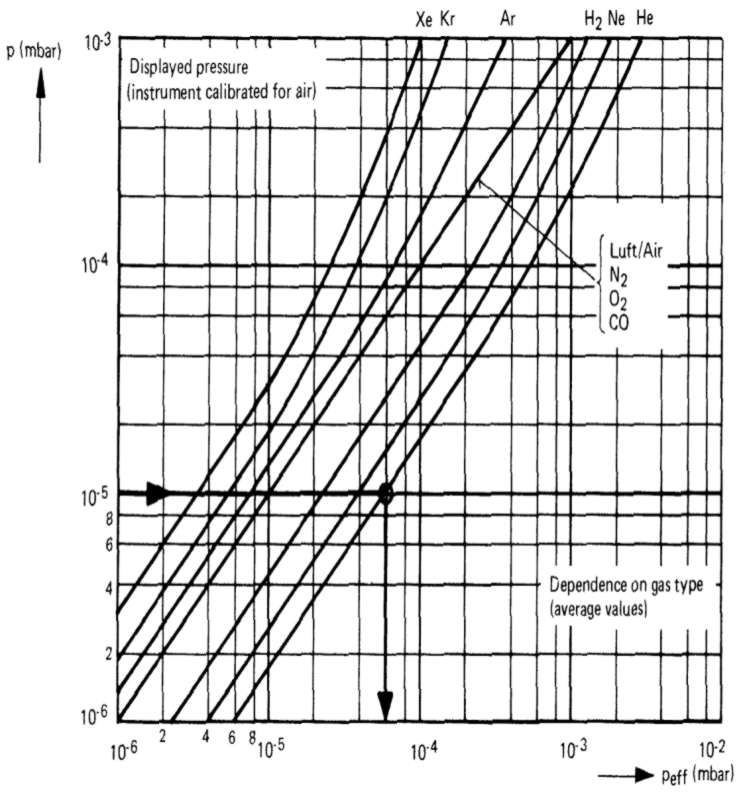

On the PKR 215 Compact FullRange Gauge 3.8V corresponds to 1.0x10-5mbar.

The gas pressure value is displayed in mbar on the TPG251 control unit.

|

|

For a regulated pressure of p, the set point SP shall be set to:

SP = 60 log10 p - 280

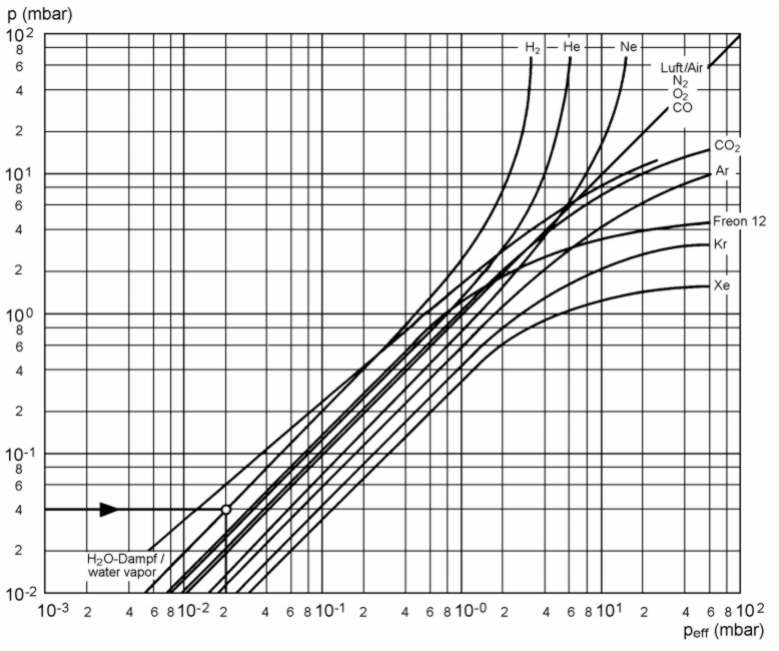

For gas other that air, N2, O2, CO2, a corrective factor shall be introduced

|

RVG040

REGULATED mbar

200

1.0x10-8 |

|

Corrective factor for gas other that air, N2, O2, CO2

|

Gas Type |

K |

Valid to |

|

air, N2, O2, CO2 |

1 |

1000 mbar |

|

Xe |

0.4 |

4x10-5 mbar |

|

Kr |

0.5 |

2x10-5 mbar |

|

Ar |

0.8 |

2x10-4 mbar |

|

H2 |

2.4 |

1x10-4 mbar |

|

Ne |

4.1 |

2x10-5 mbar |

|

He |

5.9 |

4x10-5 mbar |

Pfeiffer singlegauge cold cathode gas dependence measurement

PKR

215 Compact FullRange Gauge

Range

(air, N2) 5 x 10-9

1000mbar

Reproducibility ~ +5%

Pfeiffer singlegauge pyrani gas dependence measurement

Setting Controller Parameters

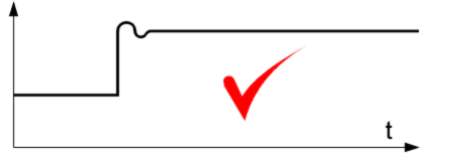

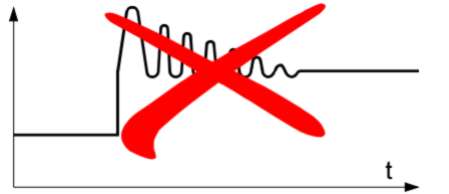

The control parameters Tn (reset time) and Vp (proportional gain) have to be set in a way that the control loop is stable (no oscillations!). The optimal control parameters depend on the extended control system.

High reset time and low proportional gain is the most stable control. Change the controls as following: lower the reset time and increase the voltage gain until the control circuit becomes unstable then reverse slightly the parameters, The optimum tuning depends also of the SET POINT.

The pressure voltage from the TPG251 Single Gauge unit shall be observed with an oscilloscope, A sudden increase of the SET POINT should not induce oscillations.

Devices tested.

Prices

Euro 2'500.00 + VAT and transport