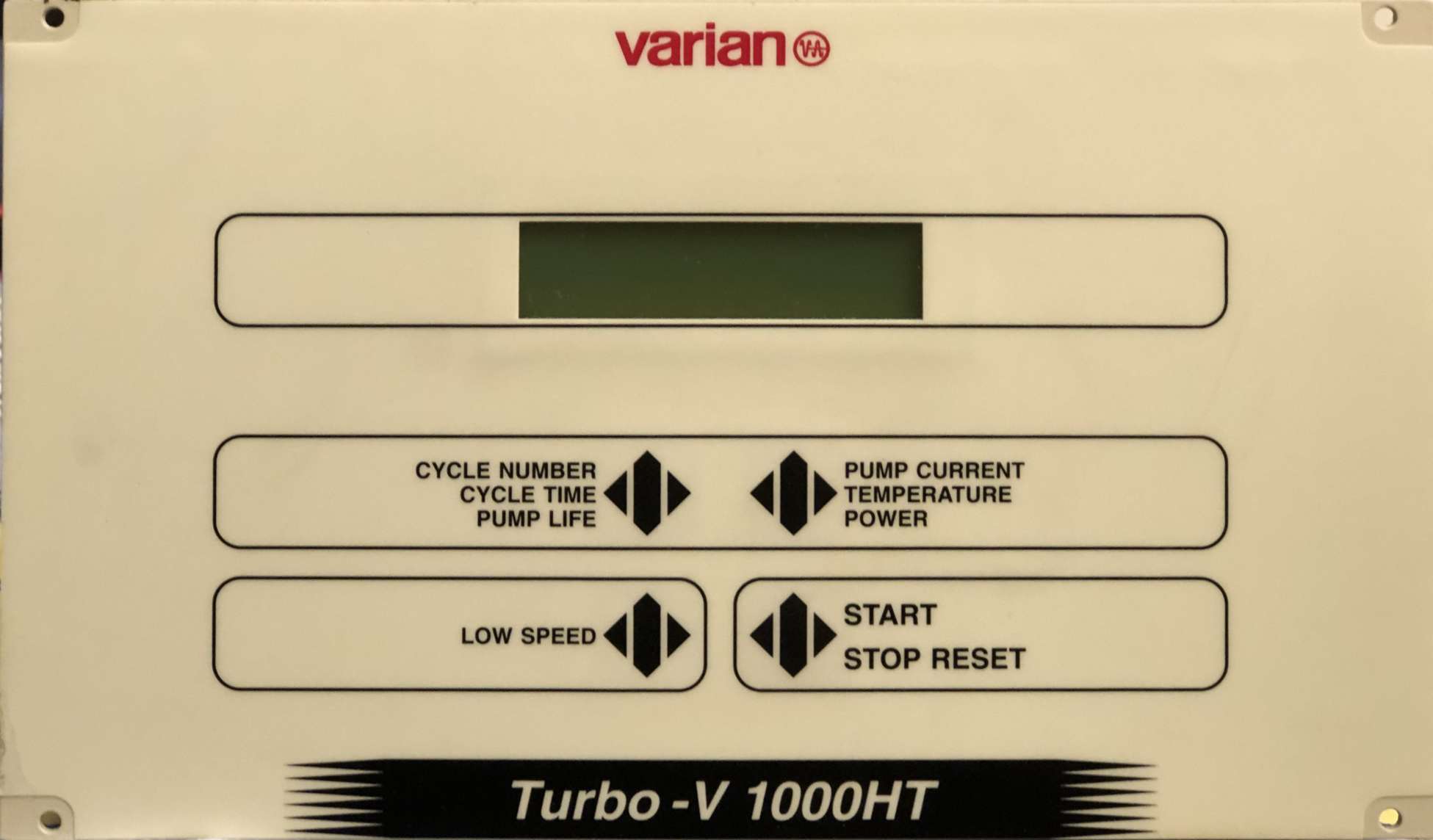

Turbomolecular Pump Varian Turbo-V 1000HT + Controller

Pumpimg speed 1000l/s

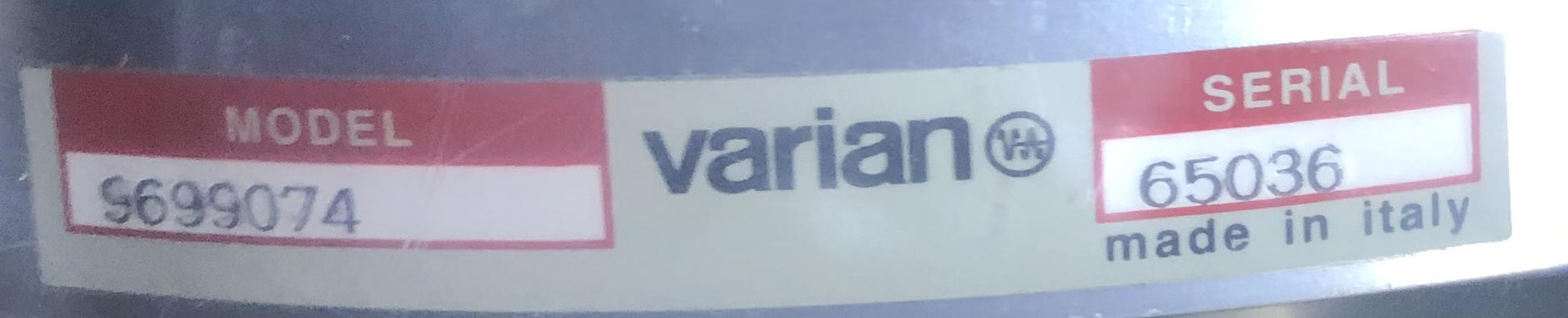

Turbo-V 1000HT

Model 969-9074 (220Vac operation)

Serial 65036

Inlet Flange DN-200 ISO

Outlet Flange DN-40 KF

The Turbo-V 1000HT series pumps are turbo-molecular pumps for high and ultra-high vacuum applications and can pump any type of gas or gas compound. They are not suitable for pumping liquids or solid particles. The pumping action is obtained through a high speed turbine (max. 38000 rpm) driven by a high-performance 3-phase electric motor.

The Turbo-V 1000HT pumps are free of

contaminating agents and, therefore, are suitable for applications requiring a

"clean" vacuum.

The Turbo-V1000HT pump consists of a high frequency motor

driving a turbine fitted with 8 bladed stages and 4 Macrotorr stages. The

turbine rotates in an anticlockwise direction when viewed from the high vacuum

flange end.

The turbine is made of high-strength, light aluminium alloy, and is machined

from a single block of aluminium. The turbine stages have six different angles,

from 44°

to 16°,

while the Macrotorr stages are in form of discs.

The turbine rotor is supported by permanently lubricated high precision ceramic

ball bearings installed on the forevacuum side of the pump. The static blades of

the stator are made of stainless steel with five different blade angles from 44°

to 16°. These are supported and accurately positioned by spacer rings. The

Macrotorr stators are in the form of selfpositioning machined discs with pumping

channels and an opening restricted by the corresponding rotor discs. These are

made of aluminium alloy.

During normal operation, the motor is fed with a voltage of 56 Vac three-phase

at 633 Hz. To reduce losses during start-up to a minimum, the frequency

increases according to a ramp with a higher initial voltage/frequency ratio. The

pump must operate with forced air cooling. A water cooling kit is available to

cool the pump in the cases where it is used under heavy load or when forced air

is insufficient for cooling purposes.

A thermistor sensor is mounted near the upper bearing to prevent the pump from

overheating. The thermistor sensor, the motor stator windings and the earth are

connected to a Turbo-V controller through a 8 pin socket on the side of the pump.

The pump is balanced after assembly with a residual vibration amplitude less

than 0.01 mm.

The pump can operate in any position and can be supported on the high vacuum

flange or on its base. The connection of the forevacuum on the side of the pump

is a KF 40 flange.

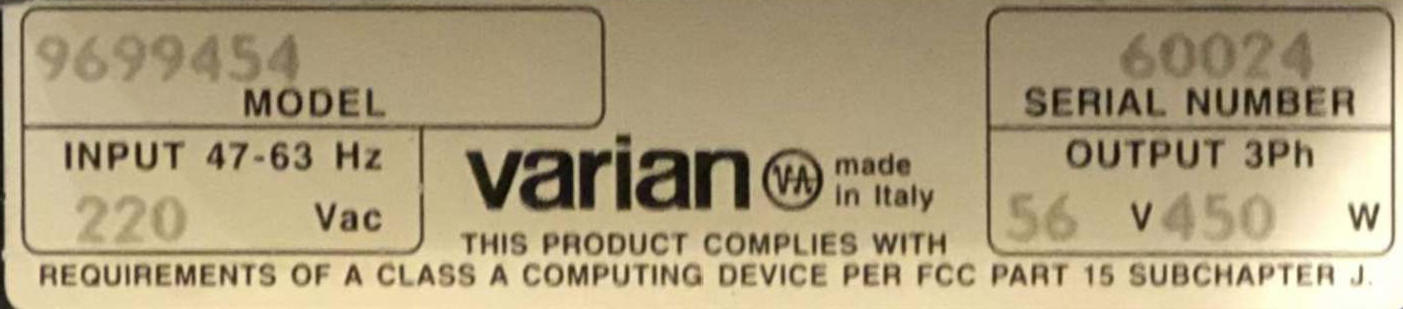

Controller

Model 9699454

Serial 60024

Price including

Euro 4'500.- +VAT and transport